In an age of severe labor shortages, few pieces of equipment are more valuable than depositors, which allow the automated repeated depositing of a consistent quantity of products rather than relying on a human being with a piping bag or a scoop.

“It helps the operators by avoiding tasks that are typically time consuming, heavy and could possibly lead to injuries,” said Luc Imberechts, owner of Torrance, Calif.-based Bakon Food Equipment.

Filling a tray with sponge batters, depositing muffin batter, icing a cake, filling a Danish, injecting jam in a donut, producing French macarons, choux or eclairs, depositing cookies — depositors can do it all, while producing huge labor savings for bakers and manufacturers.

A perfect fit for commissaries

Increasingly, commissaries, central kitchens and other offsite facilities that supply value-added foods to grocery perimeter departments are turning to depositors to meet these and other needs.

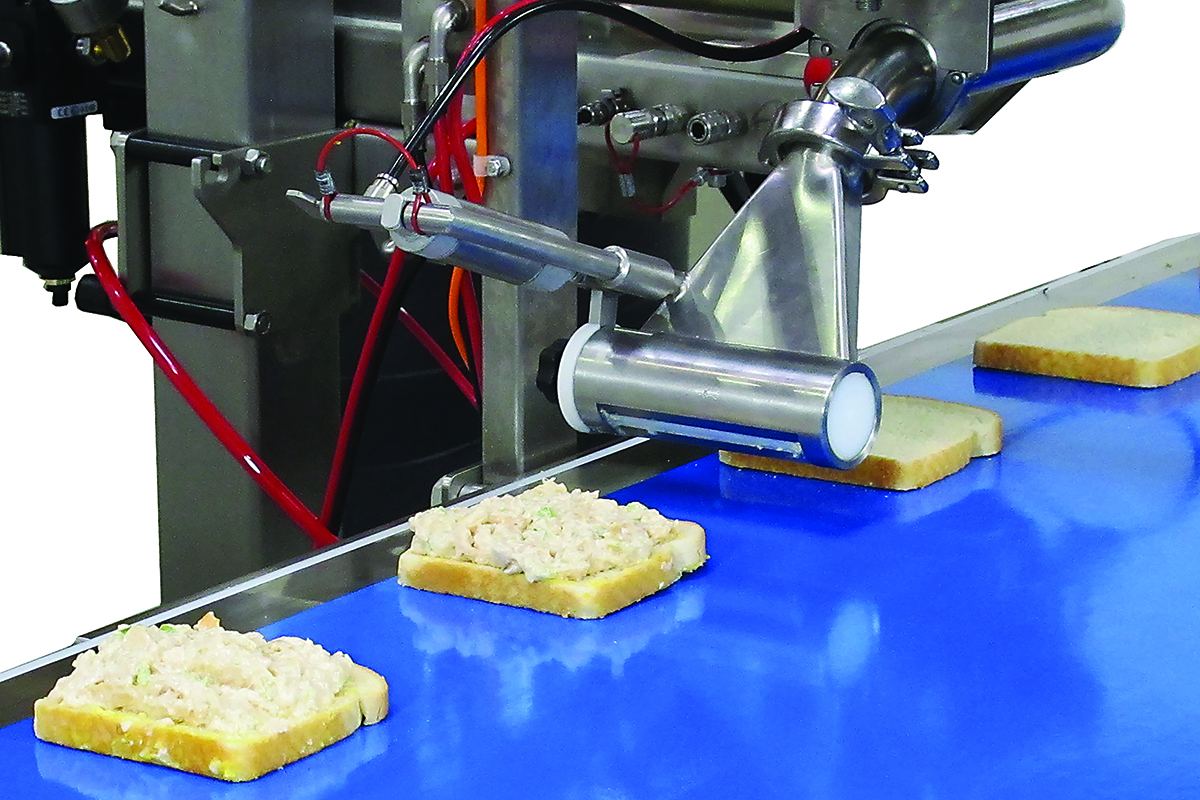

Delta, BC-based Unifiller Pro Series Food Service Depositors are ideal for commissaries supplying sandwiches to supermarket delis, said Sonia Bal, the company’s director of global marketing.

The depositors work ideally in cold temperatures and offer many food safety features for easier maintenance and cleaning. They’re also perfect for deli products portioning such as soup filing, salsa, guacamole, dip portioning and deli salads portioning.

Constructed with the highest food safety and sanitation standards in mind, Bal said the Pro Series includes angled surface covers, which eliminate pooling of water and food particles, stainless steel, tool-free design makes maintenance, change-over, and disassembly quick and easy.

Image courtesy of Unifiller

Image courtesy of UnifillerFull wash-down capabilities and a design philosophy that focuses on the fewest parts to maintain and clean, allow for quick sanitization for maximum uptime.

“The series’ versatility lends itself to various configurations through the addition of attachments like spreader nozzles for sandwich fill spreading — egg, tuna and chicken salad, for instance — injection needles, cake heads, diving nozzles and more.”

The Pro Series depositors are also ideal for environments with extreme temperature requirements, featuring an upgraded pneumatic control systems intended to work in hot and cold environments, substantially reducing the wear and tear caused by moisture build-up, caustic cleaning processes and daily use.

In central commissaries or kitchens, multi-lane depositors are ideal, Imberechts said. They can be combined with a release agent sprayer upstream, and possibly a denester, which makes for a very versatile production line for filling full sheet trays with batters, for instance, or producing large volume of muffins.

Gearwheel depositors, Imberechts said, are extremely consistent as they apply a gentle pressure on the product to deposit. They’re ideal for applications where the product is heavier or contains a lot of air. French macarons, choux, eclairs and cookies are all possibilities.

They can be delivered in various configurations: heated hoppers, rotary template and wire cutting systems, among others.

The Drop TT (table top) is Bakon’s small solution, while on the larger models the company offers C-frame solutions and H-frames in the case of oven belt depositing. This is very common for cookies, Imberechts said.

“Once combining two oven belt depositors back to back, the possibilities are nearly endless.”

A solution for every need

Bakon offers its customers depositors to meet all of its many depositing needs, and the company’s product roster continue to evolve to meet ever-changing demand.

Bakon’s piston depositors have a large scope of applications, Imberechts said. They’re preferred when the products to deposit are flowable and will fill the cylinder of the depositor by gravity — things like cake batter, muffin batter, fruit filling, icing and mousses.

They also offer the advantage of being gentle on the products and allow the depositing of products with particulates, Imberechts said. For instance, one can deposit a cherry filling with whole fruit with such a depositor.

Bakon’s range starts with a small table top unit, the BD 3. The innovative BD 5 is basically a transfer pump combined with a depositor and allows to deposit directly from a pail or mixing bowl. The BD 7 is easy to operate and is very reliable, Imberechts said.

Image courtesy of Bakon Bakon’s BD 9 depositor, meanwhile, is the most advanced single shot depositor on the market. With a sophisticated depositing technology to control depositing speed, vacuum, filling speed, acceleration speed for the deposit and working height of the machine, the model is ideal for cake decorating.

Image courtesy of Bakon Bakon’s BD 9 depositor, meanwhile, is the most advanced single shot depositor on the market. With a sophisticated depositing technology to control depositing speed, vacuum, filling speed, acceleration speed for the deposit and working height of the machine, the model is ideal for cake decorating.Due to the unique touch panel together with the advanced software system, it’s possible to program 99 recipes and parameters, and it can easily be integrated in cake lines.

Cake innovations

A more competitive landscape has been driving the need for innovative cake production technology, Bal said. The integration of servo systems has allowed Unifiller to develop its ACIS (round cake decorating) and SKIL (sheet cake line decorating) lines.

Both lines increase cake production throughput via a servo-controlled machine that offers recipe recall at the touch of a button, making it possible for a bakery to program all its cake decorating specifications into a line, and adjust the line setting to each products’ profile.

“Servo systems can also collect and provide useful data on production rates, cycles and deposits,” Bal said. “These depositors offer a user-friendly PLC screen and can be integrated into a larger production system in responder mode.”

Unifiller’s best depositor lines for supermarkets still tend to be those systems that are for cake production, whether round, sheet or bar, and are typically for post bake production related to fast accurate cake decorating, Bal said.

Automation, automation, automation

Given recent changes in the market, Bakon has seen a surge in demand for full production lines, Imberechts said. Lines are built around a conveyor and combine several kind of depositors in addition to other spraying, cutting, enrobing or dipping machines.

“Automation is required for successful operators in this challenging environment,” he said. “In-store operators are focusing on solutions that are very easy to operate like the table top BD 3 or the Drop TT, depending on the product mix that needs to be produced or finished in store.”

Bakon expects further automation in several areas, including:

- Cake lines

- Cookie lines

- Gearwheel depositors for full slabs

- Multi lane piston depositors for muffins

- Oven belt depositors

Several steps of the cake line can be automated successfully by adding a robotic approach to the line, and Bakon offers these integration solutions. Imberechts also sees more demand for individual desserts and verrines.

Another trend Bakon was ready to pounce on when it emerged is the need to add an ultrasonic cutter at the end of such production line.

With the shortage of qualified staff, Unifiller’s customers are telling the company that they are having difficulty keeping up with demand, while ensuring that their remaining staff still remain happy enough to keep working there.

As a result, initiatives to ensure staff aren’t burning out, are kept safe and are happy are being implemented. Among those recruitment and culture initiatives is offering higher wages, so costs of operations are going up.

That, Bal said, makes automation more important than ever. Production shifts that were running nonstop decorating cakes by hand can implement simple cake decorating automation through standalone systems like the COM or through fully automated systems like the ACIS, SKIL or Flex line.

That makes it possible for management to still meet production quotas without sacrificing the mental or physical health of their staff. Repetitive hand movements (twisting or turning roundtables or cake icers or squeezing bags) are replaced with automation that ices, borders and writes on a cake reducing injury and strain.

Solving the problem of human error

Another trend Unifiller is keeping a close eye on is tighter quality control — specifically, leveraging pumping, portioning and decorating lines to offer a practical solution to the problem of human error.

“Workers tire, burn out, get distracted or lack consistency. We’re staying on top of this by offering servo depositors that can be programmed to always meet specific and repetitive product parameters.”

The company has also seen the rising popularity of servo-driven machines with programmable logic controllers (PLC). The addition of these technologies helps companies save and repeat processes, gain speed, reduce changeup time, and improve product consistency.

“Servo- based depositors aren’t affected by fluctuating air pressure from the compressed air system and are able to give the most consistent and repeatable depositing solutions,” Bal said. “In addition to benefits like recipe storage and higher output, servo-driven machines offer the opportunity for sites to integrate various processes and systems. The advantage of system integration – using software – is that site operators can access and manage the whole line at the touch of a button and standardize processes.”