KANSAS CITY - COVID has created a host of problems for companies and people throughout the food industry. But the pandemic has also led to some opportunities, including for commissaries, central kitchens and other offsite facilities that supply prepared and other foods to retail grocers.

“There have been niche opportunities for commissaries that have the capacity to shift and adapt to the new business challenges,” said Miguel Lutz, territory sales manager for Delta, B.C.-based Unifiller Systems Inc. “Many commissary kitchens have the expertise, sanitary requirements, certifications, and sometimes the level of automation required to produce high quality products that are sought to by retailers.”

Restaurants and other traditional lunch options are limited due to lockdown closures, and more people are relying less on dine-in and more on prepared foods.

As a result, Lutz said, grab-and-go has become one of the fastest growing industry segments, and retailers are looking to cope with the added volume.

“Off-site facilities that have the capacity to shift production to take on these new opportunities are taking advantage.

Additionally, some of the larger companies have dropped out of certain markets due to production constraints to focus on their core business.”

Commissaries love Unifiller’s solutions to their sandwich production problems because of their versatility, said Terry Neithercut, business development manager.

“Sandwiches have a short shelf date, so while these commissaries make a lot of sandwiches, there is a lot of switch-over,” he said. “Unifiller equipment is the perfect fit. Not only is our equipment easy to sanitize and switch over, they can easily be set up to portion other items such as flowable salads (macaroni, potato), dressings, dips, soup, etc.”

Unifiller is seeing large producers dropping out of segments where there is steady demand (peanut butter and jelly sandwiches, e.g.), leaving a void that others are looking to fill.

Companies that can rapidly start producing, he said, will take some of those contracts. Typically, that kind of demand is met by companies that have or are willing to invest in equipment to automate production.

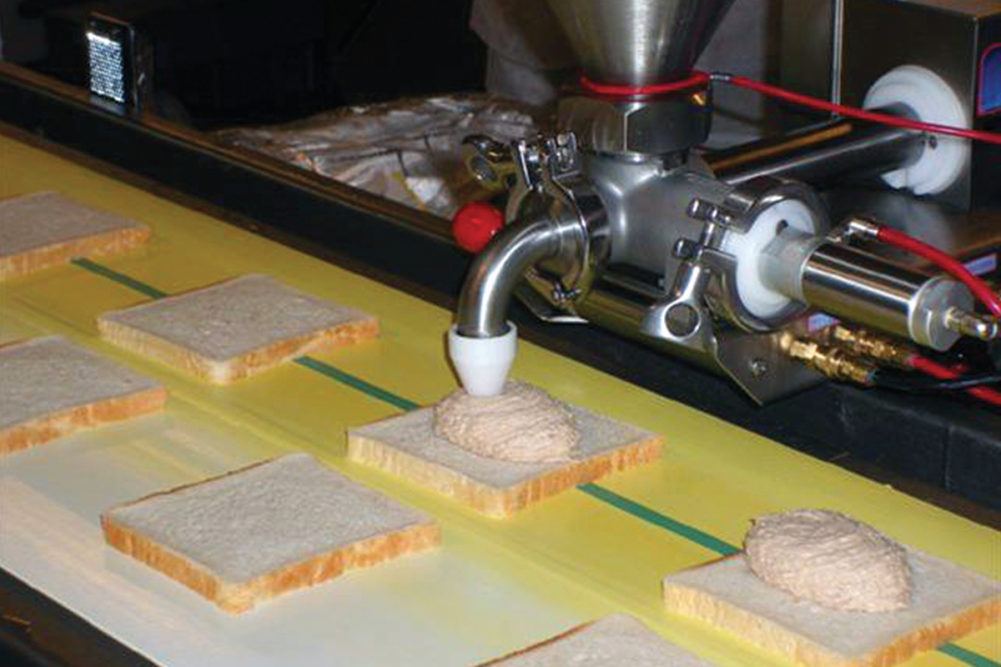

That’s where Unifiller comes in. For sandwich production, one great solution, Lutz said, is the Unifiller Pro 1000 machine, either pneumatic or servo, for spreading products onto sliced bread or open rolls.

The process works directly over a conveyor belt, where a photosensor sees the slices moving on the belt and then automatically triggers deposits.

When it comes to nozzles, Unifiller nozzles can spread salads (tuna, egg or chicken), spray mustard or mayo, and deposit peanut butter or jelly.

Lutz said there’s been a shift in the industry in favor of servo machines because of their ability to save recipes.

“It gives way to very fast changeups between production runs, making for less downtime and higher productivity,” he said. “Servo machines have more power and that helps to deposit thicker products. We can control the speed of the deposit batter and, in some cases, use options like suck-back or pre-charge to deposit difficult products.”

That gives Unifiller more options to help with each customer’s need, he said.

“Because of the pandemic, companies are looking into automation of their process, and we have the tools and the people to set them up with the correct solution.”

A Guide To Sandwich Food Safety

By Hygiene Food Safety

We always tend to think that sandwiches are low risk and can be left out for as long as is needed. Unfortunately, sandwiches are much riskier than we think they are.

There is a microbiological risk in sandwich making that affects sandwich food safety. In reality, it is the sandwich fillings that create the risk. Sandwich fillings are perishable, uncooked products that usually undergo no heating or sanitizing.

Let’s consider the most common fillings:

- lettuce

- cheese

- cucumbers

- chicken

- mayonnaise

- deli meats

Each of these foods has at some stage or another been implicated in food poisoning outbreaks. Lettuce and cucumbers are the most common foods that carry E.coli O157:H7, which is the pathogenic strain of E.coli that causes internal hemorrhagic bleeding of the gut.

This type of bacteria occurs naturally in the soil and can cause contamination from unwashed vegetables.

Chicken, mayo and deli meats have been implicated in serious cases of Listeriosis, Salmonellosis and a number of cross-contamination cases involving Campylobacter. It then seems strange that we would consider sandwiches as low-risk foods. There are definite microbiological risks that can affect sandwich food safety. Adding to the concerns are how sandwiches are treated during preparation and display. Sandwiches are usually prepared in large portions.

Depending on the amount prepared this can usually take up to two hours or more. This already means that these fillings have been at ambient temperature for a long period.

Sandwiches are usually prepared by hand. How often would the chef wash their hands between handling the different food groups? Sandwiches are then plated, covered and then left out until needed. When serving sandwiches these are also usually hand dished. Meaning more opportunity for cross-contamination. Let’s consider these items in terms of a salad. By law, salads must be held and displayed below 5° C (41 °F).

This is because of the potential risks of allowing bacteria to grow to high levels causing food poisoning. Salad items are hardly washed before use and never cooked.

Like most hygiene and food safety requirements, food preparation requires planning and forethought. In this case, a few recommendations to be considered.

Sandwich fillings should be pre-prepared, kept in a fridge until ready to put together and serve. This means slicing the cheese, portioning the lettuce, cutting the cucumbers, etc.

Sandwiches should be displayed cold, as you would with salads, yet the bread presents difficulties in doing so, which generally relates to quality.

The danger zone for the growth of bacteria is between 20 – 45 degrees C (68 – 113 degrees F). This is the range at which food-related bacteria grow most rapidly. At the very least, all foods must be kept out of this range.

From a real risk perspective, cold foods — in this case sandwiches — only start to show risk once above 10 degrees C (50 degrees F). Bacteria, in general, will not grow or will at least be minimized within this range.

This does mean that it is time-dependent, meaning that bacteria will eventually grow below 10 degrees C (50 degrees F) after a certain period.

Finished products should be transported, distributed and displayed below 5 °C (41 °F) in order to protect them from contamination and deterioration.

Where possible, transportation, distribution and display units of finished products should be equipped with accurate and reliable temperature control and monitoring devices.

To prevent deterioration, the distribution and sale of finished products should be carried out in a first-in-first-out basis. Appropriate and adequate chillers and freezers should be available in authorized retail outlets selling sandwiches.

Hygiene Food Safety is an organization devoted to educating professionals and consumers about food safety best practices.

This story was featured in the November issue of Supermarket Perimeter. Click here for the full issue.