Lightening the load when it comes to slicing doesn’t require major capital spending. In fact, the return on investment (ROI) can be quick, especially for those medium-sized bakeries with multiple hand-fed reciprocating slicers that run 10 loaves a minute or less.

“They could save on total labor costs by upgrading to an industrial grade slicer/bagger where a single machine could do 40 to 55 loaves per minute,” said Harold Schmidt, equipment applications engineer, Bettendorf Stanford. “This could mean going to one of our band slicers like the Model 40 or BSI 75 or BSI-75B, or if they have a hard-to-slice product, then they could use our industrial grade reciprocating slicer, the RSC. Switching the type of equipment could take a six- or eight-person operation down to a three-person operation that could get the job done in less time than before.”

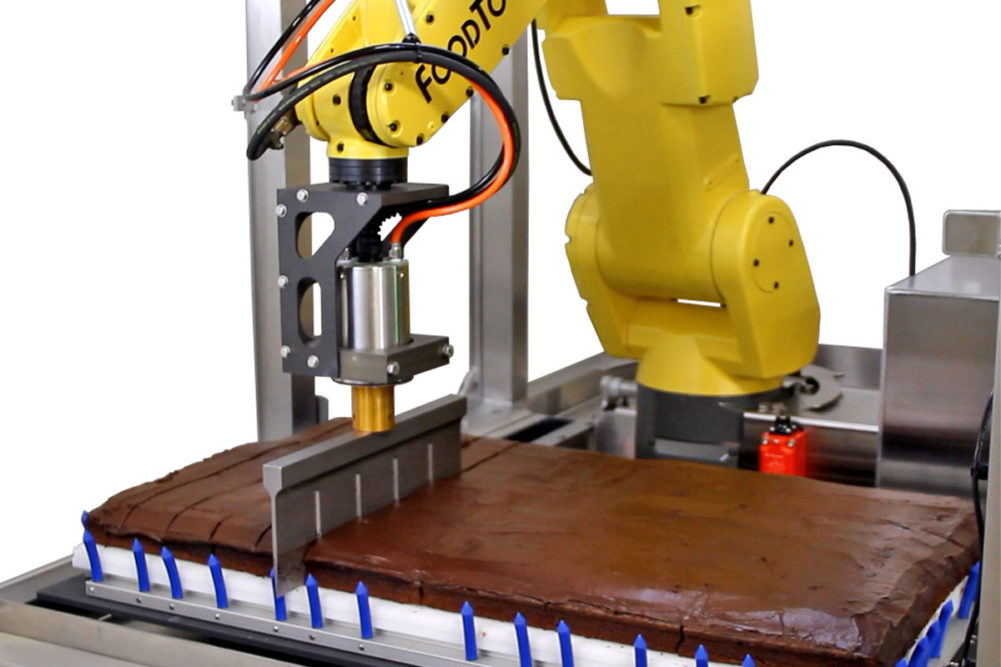

Matt Wermund, general manager, FoodTools, noted that one operator can run several standalone semi-automatic machines concurrently or supervise a fully automatic inline system that portions a continuous feed of product.

The key, he added, is to choose an automated machine that not only handles a bakery’s current output but has room to grow as the business expands.

“We are integrating more conveyor systems in our inline machines to automate onload and offload and efficiently convey the portioned product to downstream processing like packaging machines,” he said.

Sandra Ryan, vice president of operations, Ryan Technology, pointed out a chute-style, tabletop slicer can slice about eight buns per minute while a rotary table slicer cuts 120 buns per minute.

“That means you don’t need as many people slicing, and they can be used to do something else,” she said. “Or it doesn’t take as long to do a run, and you can increase your volume.”

This article is an excerpt from the November 2021 issue of Baking & Snack. To read the entire feature on Slicing & Cutting, click here.