KANSAS CITY, MO. - The coronavirus (COVID-19) outbreak has driven home the importance of tamper-evident food packaging in the supermarket perimeter and throughout the food industry.

“Tamper-evident packaging is serving the nation,” said Cindy Blish, associated brand and communications manager for Shelton, Connecticut-based Inline Plastics. “With the closing of traditional channels — foodservice, colleges, sporting events, entertainment industry, sit-in restaurants — we have experienced a significant shift and are now much more reliant on carry-out services.”

According to Freshop data cited by Inline, the food industry is seeing an 80% growth of online sales and a 10% increase on deliveries in both retail and 3rd party services, where retailers and third party providers are splitting costs (e.g. DoorDash and Grubhub).

“The phenomenal increase in online sales provides Inline with an opportunity to address both the functional and emotional benefits in a way that will ease the minds of consumers at a very unprecedented time,” Blish said.

Driven by consumer fears related to COVID-19, food delivery services country-wide have reached 31% of US households, and almost 40 million in total have used an online grocery delivery or pick up service over the last month.

“The need for consumer confidence that the food they order will be safe has resulted in an increased demand for safe tamper evident packaging,” Blish said. “Food packaging touches any number of hands before reaching the consumer, especially via ecommerce delivery, making the security provided with tamper-evident, tamper-resistant packaging more important than ever.”

Peace of mind

Packaging that keeps foods and the people who eat them safe is always important, said Jazmin Lofti, marketing coordinator for the Mansfield, Mass.-based Lacerta Group Inc.

With the coronavirus outbreak, it’s even more important.

“Especially now with so much uncertainty, it's peace of mind for the customer,” Lofti said. “You don't know what's been touched by a previous customer of the grocery store, it's reassuring that you the know the product you are buying inside the package hasn't been touched by someone else who may not have even known they're infected.”

Lacerta is still running its stock tamper evident line, Fresh n' Sealed, and also its custom tamper evident two-piece containers.

“Times are uncertain but we're here to help,” Lofti said.

"We have seen an increase in tamper-evident food packaging as many grocery stores are no longer allowed to have self-serving salad or soup bars," said Derek Skogen, senior product manager for Madison, Wis.-based Placon. "These stores are now having to pre-pack the salads and soups to then place on the retail shelves for sale."

During COVID-19, Skogen said, Placon has seen a significant increase in overall food packaging demand from customers. With many consumers stocking up on products during the “Stay at Home” they are tending to buy more during each store visit.

"Prior to COVID-19 we were seeing more demand in general for tamper-evident packaging, which is why our most recent product line – CrystalSeal® reFresh® Parfait Cups each have a tamper-evident feature to ensure the base and lid form a secure lock with tamper-evident tab to notify a customer if it has been tampered with prior to purchase," Skogen said.

Placon currently offers a variety of tamper-evident products in its CrystalSeal Tamper-Evident product line that offers retailers options to hold cut fruit, nuts, salad mixes or other pre-made convenience type items. With its newest line of parfait cups, which are ideal for on-the-go convenience and snacking (growth markets), all cups have the tamper-evident feature included on them to ensure products are kept safe.

"With the tamper-evident seal, we can actually promote a longer lasting product, because consumers cannot open/close the item at point, which allows no outside air or moisture to get into the packaging."

One of the latest innovations from Placon is its parfait cups. These are different than what is in the market today, Skogen said, for a number of reasons:

- The pedestal cup offers an inverted base or lid option that can be set either way on the shelf and can be stacked upon one another to increase merchandising space for retailers

- The cups offer a tamper-evident tab feature to ensure foods stay protected and fresher for longer

- A single or two-compartment insert option or inside insert lid are available to go with any cup as an added packaging accessory. These insert trays help hold dry or wet ingredients such as sauces or fresh fruit that you may want to add or dump-in to the main cup ingredients later on when ready for consumption. The insert lid option is a great add-on that gives the retailer a way to hold ingredients or sauces/dips within the package to showcase better at retail.

- Each cup has a slight angled curve to increase the crush strength of the cup and allow retailers to hand pack each cup without crushing the cup during loading. Other designs in the market today use a rib or flute design that tends to decrease product visibility and overall package design. Our cups are clean with no angles or obstructive markings on the cup.

- Each cup is made using 75% or more post-consumer recycled PET.

Beyond tamper-evident

Inline, Blish said, does more than just provide its customers with tamper-evident containers. Inline packs also travel well, keeping foods secure, preventing leaks and improving shelf life — all while reducing food waste.

During the outbreak, Inline has been working closely and effectively with our customers to meet the increased demands being forecasted to provide product in a timely manner.

“We’ve been able to be responsive to those needs and continue to maintain a positive inventory status on the majority of our Safe-T-Fresh tamper evident line.”

In fact, Inline’s fill rates have remained at a very strong overall 99%.

COVID-19, Blish added, has created a vital need for packaged food products and has challenged manufacturers to meet the demand for these and other consumer products.

Because Inline is engaged in the business of food packaging, it’s considered an essential business, she said.

“That means we have a special responsibility to continue servicing our customers. We fully appreciate our responsibility to assure supply of our products in this time of need.”

Placon offers a variety of tamper-evident products other than the new cups. There are CrystalSeal Tamper-Evident options for products to hold cut fruit, nuts, salad mixes or other pre-made convenience type items.

“With the tamper-evident seal, we can actually promote a longer lasting product, because consumers cannot open or close the item at point, which allows no outside air or moisture to get into the packaging,” Skogen said.

Meeting the need

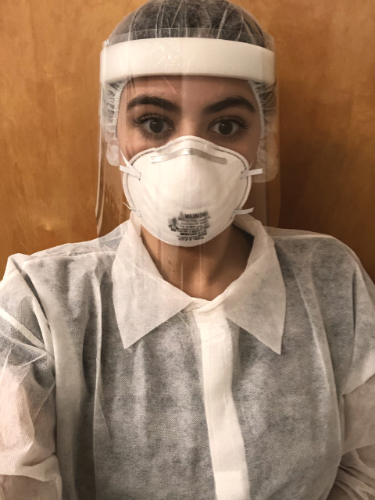

The COVID-19 pandemic created an acute shortfall in needed protective-ware. In response, Mansfield, Mass.-based food packaging manufacturer Lacerta rapidly developed face shields to offer to hospitals and healthcare professionals.

The company then learned of a similar need in the food sector, especially grocery and foodservice. The masks then were made available to workers in those channels.

Shields are made from food grade PET material with an anti-fog coating. It’s the same material that soda bottles are made of and is widely used in the food industry. PET has excellent clarity and moisture and oxygen barrier properties, according to Lacerta.

Recommended for single use, the shields are made of a piece of plastic with slots cut in the back where users can attach the band together. A second piece can be comfortably worn to keep the shield away from the face.

The shields are designed to work either with or without a foam forehead band. Since beginning production March 26, Lacerta has produced about 100,000 shields per day with capabilities to ramp up to 500,000 per day

“We saw the shortages and the need to get PPE to healthcare workers immediately,” said Jazmin Lofti, marketing coordinator for Lacerta. “We’re fortunate to be in the position to react quickly and efficiently. We produce the anti-fog plastic in-house, eliminating lengthy lead times, and we’re able to scale up to meet the demand of the healthcare system.”

This story is from the May issue of Supermarket Perimeter. Check out the full magazine here.