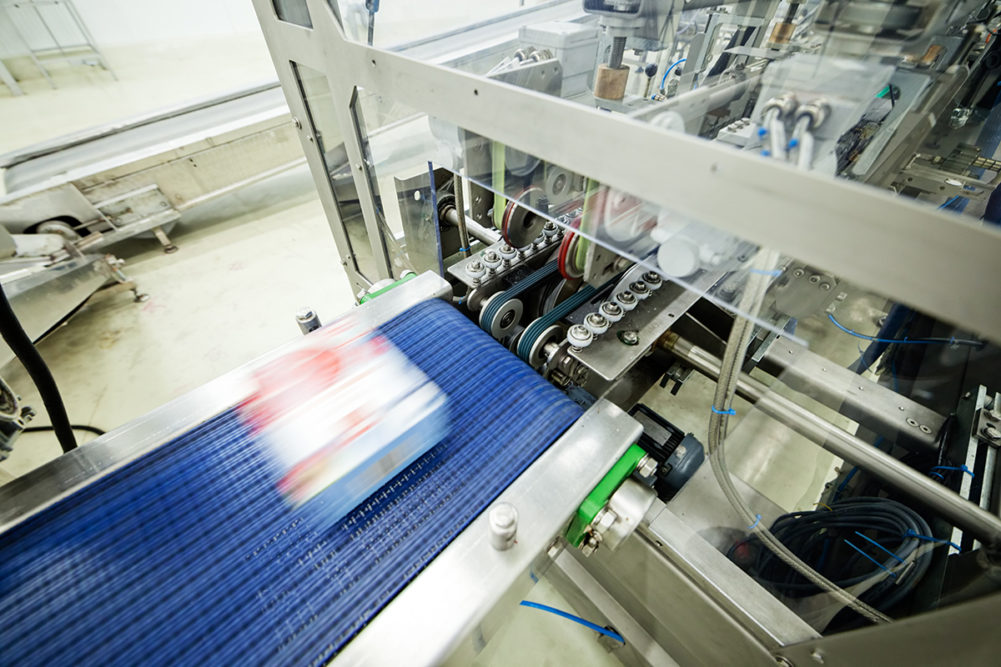

Mettler Toledo’s new Integrated Mark & Verify systems and software can help food manufacturers meet ever-changing product safety and compliance requirements by making it easier to integrate code marking and verification capabilities into their production lines.

Primarily designed for the pharmaceutical industry but with applications in food and other industries, Mark & Verify systems enable the printing and verification of 1D and 2D codes and alphanumeric text such as those used for accurate identification of individual products (serialization) and those aggregated into containers such as cases or pallets (aggregation).

In addition to these reference checks, integrated smart cameras allow for both presence and quality checks – verifying the presence of required labels and information, and that printing and labelling quality is high, with no damaged labels or smeared ink.

Market requirements require manufacturers to be able to track individual products throughout the production and supply chain, facilitating simpler and more targeted product recalls where necessary, and improving levels of product safety. The new Mark & Verify systems enable manufacturers to integrate these capabilities seamlessly into existing production lines with the minimum of disruption for installation.

“Our restructured Track & Trace portfolio allows customers to identify the right solution for their needs more easily as well as having a wealth of information available at their fingertips on our new website,” said Andreas Bechthold, general manager at Mettler-Toledo PCE. “Whether they are in pharmaceuticals or any other sector with increasing Track & Trace demands, they will now find the solution to their traceability needs quicker and easier than before, using our expanded and refreshed online portfolio.”

The new systems include:

- T51 Integrated Mark & Verify: Systems are suitable for the inspection of codes on oriented products such as cartons, labels, cases and pallets. They can be easily integrated into production lines or packaging equipment and can be linked with existing printers. In addition, multiple sensors such as smart cameras, barcode scanners and machine readers provide support for Presence, Quality and Reference Checks. Systems are capable of throughputs of up to 300ppm, supporting Good Manufacturing Practice (GMP) requirements and are easily upgradeable to a serialization system.

- T61 Integrated 360 Mark & Verify: These systems are ideal for the inspection of round products such as bottles and vials up to a maximum product height of 230 mm and width from 6 to 110 mm. Systems use six image sensors to capture a full 360o view of the product. The inspection head can be installed over conveyors, into new equipment or on a standalone frame with minimal space requirements. Moreover, they can be easily integrated with existing printers to deliver Presence, Quality and Reference checks. Capable of throughputs up to 500ppm, these solutions also meet GMP requirements and are upgradeable to a serialization systems.

- PCE Line Manager - Mark & Verify: This pre-installed software package provides comprehensive quality control management when used with Mettler-Toledo Mark & Verify systems. The solution manages Presence, Quality and Reference checks, with the capability for multiple inspection options (for example, code, label, blister and text inspections). For a future-proof solution, it can be upgraded to PLM Serialization or PLM Aggregation when required, giving users a familiar intuitive software interface capable of performing track and trace requirements.

- T16 Manual Multi-Aggregation: These systems include an automatically focusing high-resolution camera and advanced software algorithms that capture and verify product codes on serialized cartons and add them to the aggregation hierarchy with a single click. With a sophisticated high-resolution camera, the T16 offers a wide field of view (600x400mm) and detailed imaging capabilities to help capture each package code. The camera can also inspect label artwork for additional quality control.