No ifs, ands or buts. That’s the purist response when asked about automating authentic artisan breads. In the real world, however, art is open to interpretation, and baking is no exception.

“Can real artisan bread be made to scale? This is a question I get all the time from bake shops that have a handful of people to companies that employ hundreds,” said John Giacoio, vice president of sales, Rheon USA. “What they don’t understand is that this question is relative to what they are doing at the moment.”

For many bakers, there’s no negotiating as to what makes a true artisan bread, including the use of clean label ingredients, long fermentation times and authentic poolish, biga and other European-style sours. However, taking Old World breads to scale involves a matter of execution, especially how bakeries make these breads in volume — and what they don’t do — that has become an age-old debate.

“If bakers are being asked by a machine manufacturer to change their formulation, they have to ask themselves why they are listening to a machine manufacturer. You should never compromise your process or your product just to go faster,” Mr. Giacoio said. “If bakers say they want to make 200 loaves per minute, we need to tell them this will compromise their quality. If the bakers and equipment manufacturers can be honest with each other, it makes for a long-lasting and profitable relationship for both.”

Nick Magistrelli, vice president of sales, Rademaker USA, pointed out that automating involves developing a careful process that does not sacrifice quality.

“It is naïve to think that a high-capacity line can achieve the same level of quality as a line with a smaller output,” he explained. “The most important factor here is for the bakers to properly explain what the goals of automation are so the equipment vendor can design a line that can meet the expectations of the project.”

In recent years, a growing number of classically trained bakers began to grudgingly acknowledge that branching out to regional or even national markets may require never saying “never” when it comes to using equipment to do some manual work.

“When bakeries take craft baking to an industrial scale, they should carefully select their equipment and make sure it is designed to respect their specific processes to achieve the required product quality,” said Marie Laisne, product marketing manager, Mecatherm. “The secret is to respect the required processing time during all steps from mixing to cooling and baking with precision.”

Baking is a labor of love, but bakers don’t love that taking craft breads to scale is so daunting in today’s economy.

“The most pressing challenge for artisan bakeries is to drive the manual labor out of the process,” Mr. Magistrelli observed. “Many of these high-quality goods have been produced over the years with labor-intensive operations.”

In addition to offering a custom system that allows dough to ferment prior to makeup, Rademaker has enhanced its DSS Low Stress Sheeting System that uses less oil than previous models and incorporates a hopper to improve dough flow while not damaging the dough structure. Most recently, the company rolled out its new rounder for making boules and similarly shaped breads.

“This new technology provides the ability to round as if a baker were doing it by hand with flexibility of speed, position and pressure,” Mr. Magistrelli said.

Rheon’s stress-free system is designed to prevent degassing or damage to the internal cell structure of long fermented, highly hydrated doughs made with natural ingredients, Mr. Giacoio said. For high-volume bakeries, Rheon’s Stress Free Artisan Bread line features a new cutting and weighing system that accurately cuts baguettes at up to 70 pieces per minute and more than 4,000 lbs an hour.

“We can cut the dough by dimension or by weight,” he explained. “If a large bakery wants to make every loaf of bread or ciabatta roll to look the same so it fits into a package, we can cut by dimension. If the bakery is looking for each piece to be accurately weighed with small artisan-like differences in shape, we cut by weight. With either method, we do not compromise on quality.”

Jerry Murphy, vice president of sales, Gemini Bakery Equipment/KB Systems, recommended craft bakers initially take an inventory of their product portfolio when planning to expand.

“It is important that artisan bakers can clearly define their unique product characteristics that are important for them and identify the specific process steps they feel are key to achieving these characteristics as a baseline for scaling up,” he said.

After evaluating their product portfolio, bakers should then work backward to find the best way to automate them, said Alexander Weissbach, head of technology, product management at Rondo’s Dough-how Center. In addition to evaluating the system’s impact on the dough, he suggested searching for those processes that ensure product consistency in industrial applications.

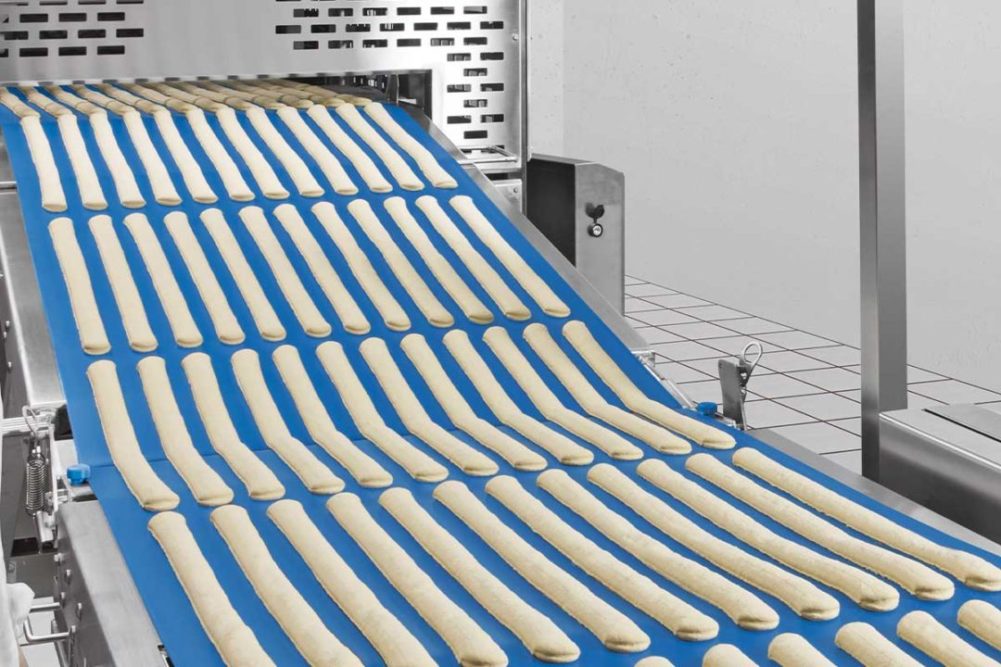

Rondo’s Smartline makeup system, he added, is designed for creating large volumes of highly hydrated doughs.

“With our no-stress line, we can really keep the dough structure intact to create these artisan breads,” he said.

Although throughput depends on the size and weight of each dough piece, Mr. Weissbach pointed out Rondo Industrial lines can generally produce from 2,000 to 3,000 kg an hour. Such volume, however, requires adequate mixing and plenty of fermentation capacity to continuously feed the operation.

“If you want to make an artisan bread like ciabatta, you need 1.5 to 2 hours of fermenting,” he explained. “You need the space to store at least 6,000 kg of dough to adequately feed a line running 3,000 kg an hour. We can run our lines faster, but you really must take care of the dough and give it the proper resting time to control the entire process.”

To produce large quantities of artisan breads, Fritsch, a Multivac company, offers the Impressa bread line and SoftProcessing Technology that adapts to a dough’s high-hydration and open-cell structure. For sheeting, Fritsch provides the SDS, a sheeter designed to produce a continuous sheet for soft doughs while still maintaining weight accuracy.

To make consistent dough pieces, Ms. Laisne said, Mecatherm’s M-NS constantly measures the density of the dough and gently cuts it to the proper weight and volume.

“This divider produces pieces of dough, which do not hold tension that could subsequently disrupt the shaping or proofing stages in a pan, faithfully reproducing the process employed by the artisan baker,” she said.

Ramping up production also requires adjustments throughout the production line.

“Even if you are running 2 tons of dough per hour, you need to make sure you automate down the line with continuous resting, proofing and baking,” Mr. Weissbach said. “Otherwise, you have too much labor involved to handle all the trays. It becomes counterproductive.”

He added that high-volume lines need enhanced communication among all equipment to operate efficiently with less labor. He suggested using software and digital controls to monitor line speed, motors and drives to ensure they are properly maintained while providing better traceability throughout the process.

Patricia Kennedy, president and chief executive officer, WP Bakery Group USA, pointed out that advances in software and other digital systems not only enhance a bakery’s efficiency but also adapt to new product changes. With WP Connect, she added, bakeries also can constantly monitor the status of the line as well as gear boxes and motors to provide preventive maintenance.

“In the past, everything was manually adjusted by the operator,” she said. “Now the line is doing this 90% by itself. With a smart recipe controller, most steps are fully automated, and the rest are done by the operator.”

Such technology wasn’t readily available in the baking industry 10 to 15 years ago when many bakeries previously installed their current artisan bread lines.

Today’s systems commonly incorporate the use of robotics for water scoring, cutting, folding, rounding, depanning and other steps of the makeup process, noted Hans Besems, executive product manager, AMF Tromp, an AMF Bakery Systems brand.

“Another nice example of new technology is also the targeted application of decoration of a bread,” Mr. Besems said. “With our Smart Applicators, seeds, corn, bran or cheese can be applied to an exact spot right on top of the bread to avoid wasting expensive toppings like sesame seeds and cheese, which can lead to big savings and a shorter return on investment on the machine.”

He said AMF Tromp designed its new artisan bread line to handle highly hydrated specialty doughs with a low-stress system that maintains all dough properties. Addressing ways to reduce waste is another big change in sheeting technology over the years.

“We even suggest process changes to reuse scrap dough into a slurry with bakeries and producers,” Mr. Besems said.