Tampa, Fla.-based Applied Data Corp.’s FreshIQ software service platform consists of six products designed to help grocery stores plan, execute and analyze their recipes and other fresh food operations, said Jesus Mathus, the company’s global head of retail solutions.

One of those products is devoted exclusively to recipe management. Applied Data’s software provides customers with centralized control of their recipe data base, including ingredients, preparation instructions, nutritional information and other features, Mathus said.

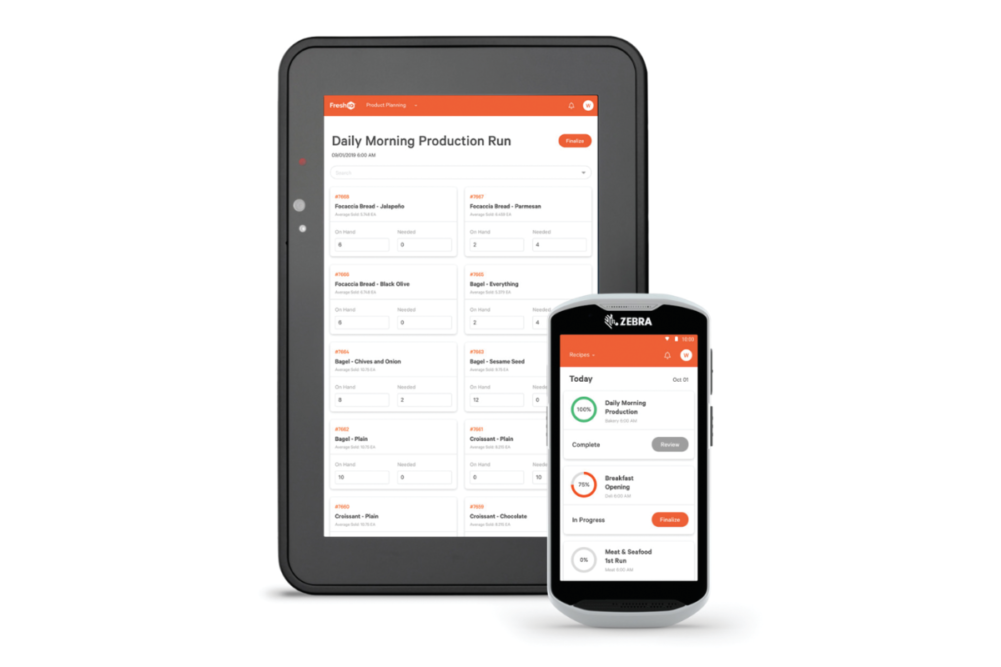

“Stores can access this information through a user-friendly mobile application available for any Android or iSO mobile device,” he said. “Our product is capable to manage the needs of centralized production, such as commissaries, as well as provides a vendor portal that allows the maintenance of accurate ingredient data directly from the suppliers.”

It’s a far cry from former recipe management practices used at the retail level, Mathus said. The old way was based on paper recipe books at stores that were updated irregularly and were limited by the type of information available (no multimedia instructions, no current prices or cost information).

Books were frequently incomplete and, as a result, stores tended to stop using them.

“In our system, any changes made by the owner of the recipe book are distributed in real time to all stores, and you can even manage different variations of the recipe of the same item depending on local preferences of your consumer or availability of specific ingredients.”

FreshIQ is the result of Applied Data’s 30 years in the fresh food industry, and it’s the only cloud solution currently on the market, Mathus said, that doesn’t require expensive on-premise infrastructure and installation investments.

It’s also, he added, the only solution of its kind that can be accessed either by a web browser or Applied Data’s mobile application. That contributes significantly to ease of use, and the program’s user-friendly interface requires minimum training, which lowers costs for retailers working on razor-thin margins.

Better in the cloud

The latest iteration of FreshIQ includes new technical features like improved multimedia instructions, extended data fields to handle nutritional and labeling information required by the US 2016 Nutritional Labeling and Education Act (NLEA) and significant upgrades to the user interface.

But the biggest technological improvement to the system, Mathus said, has been the transition from an “on-premise” software product to a native cloud application designed to handle Applied Data’s customer data in a secure and efficient multitenant environment.

“This transition will eliminate many of the hidden costs and challenges that retailers have to face when managing on premise applications, such as hardware and database license costs, backup, DR and high availability solutions to support such applications,” Mathus said. “By migrating to the cloud, we provide the best infrastructure and service to maintain (retailers’) applications running efficiently.”

Applied Data also has a clear road map for how to make FreshIQ even better over the next 18 months, Mathus said. The company is in constant contact with its customers to incorporate new ideas and best practices into its products.

“One of the biggest requirements from our customers on recipes has been to incorporate ‘made to order’ functionality to provide higher flexibility to customers to prepare their meals, particularly when they order online,” he said.

Recipe management is just one part of Applied Data’s fresh item management suite of products, Mathus said. Leading retailers that strive to improve the profitability and efficiency of their entire fresh foods operation, he said, understand that they need to automate the full process with things like label printing, inventory and waste control, production planning and automated ordering — all of which are offered on the FreshIQ platform.

Commissary and grocery versatility

More than 7,500 grocery retail and other sites in North America run the Periscope recipe management software created by Invatron Systems Corp., Mississauga, Ontario, Canada, said Kurt Brands, the company’s chief operating officer.

The Periscope platform, he said, “automates replenishment functions for everything in the store, whether it’s production, ingredients to the back door, ingredients for recipe-based items, boxes of beef, case quantities of bananas or traditional UPC-based items around the perimeter.”

The same platform is used to do central production via commissaries, central kitchens and other offsite facilities that supply prepared and other foods to grocery retailers, Brands said.

Periscope works on both “pull” and “push” models when it comes to sourcing from commissaries and central kitchens.

In the “pull” model, Brands said, stores essentially treat commissaries as warehouses. Commissaries handle centralized large-scale production, leverage it for the individual store level, then aggregate it and replenish for future production needs. In the “push” model, store workers unload their daily delivery from the commissary.

Working with a recipe management platform like Periscope delivers “good forecasting, maintaining good inventory and thriving with a just-in-time model,” Brands said.

The commissary model is definitely an expanding one for many of the nation’s retailers, Brands said. Many larger retailers have their own commissaries, handling production for multiple stores to drive labor and other efficiencies.

“At the commissary level every retailer figures out what works for them, as far as quality. Some many want to manufacture all of their inhouse dips and sauces internally, with the production instore, but what is most important is consistency of taste, so it gets centrally made, but the production is done at the store, maybe every two or three hours.”

The right ingredients at the right levels in the right places

At the end of the day, Brands said, the ability to have all of the appropriate ingredients at the right levels at the right locations is paramount.

Brands cited a retailer’s instore deli sandwich program as another example. Ingredient quantities must be presented to workers in a way that makes sense to them. The order from the supplier may be for 18 cases of hothouse tomatoes. But when you go to give the production report to the people in the commissary, the direction is: we need to slice up 120 tomatoes.

“That’s the real value add of recipe management,” Brands said. “Not only getting the right quantities in place, but also the consistency and the operational value that you can provide to the people actually doing the work.”

What Periscope delivers as its key value proposition, Brands said, is a live system that integrates upstream data management, getting live updates, changes in cost and suppliers and other data crucial to accurate recipe management that maximized efficiency and minimized waste.

“We have the ability to quickly recalculate quantities, nutritional facts, costs,” he added. “When we go into instore production at the operational level, whether it’s a commissary or a store, let’s say you need to make 120 sandwiches of various varieties. You need to be able to tell your workers that they have to pull nine loaves of bread, 27 slices of ham, 32 of turkey. It optimizes the production process.”

As recently as five years ago, grocery stores and commissaries had a lot more liberty in how they made their value-added products for the grocery perimeter, Brands said. All that’s changed.

“People with us know that longer-term automated replenishment in the perimeter in the store is where they’re going,” he said. “You have to leverage technology. The average tenure of deli managers (in many chains) is less than a year. You can’t have that person making their own decisions about recipe management.”

Total integration, consistency and quality are also paramount from food safety, traceability and other standpoints, he added.

“You can’t just go in and change recipes without multiple levels of approval. People want to centralize that whole process, Five years ago stores had a lot more liberty in how they made product. That’s all gone now.”